史密得烤漆房S-58烤漆房,史密得

| 外型尺寸(mm) | 内径尺寸(mm) | 大门尺寸(mm) | 烤漆总功率(kw) |

| 7000×5300×3300 | 6900×3900×2800 | 3000(w)×2700(h) | 10Kw |

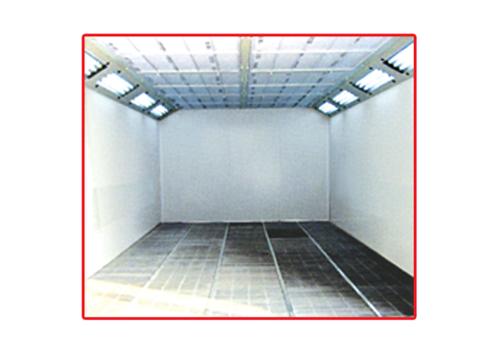

| 房体结构 | 1、墙板:采用阻燃型聚苯乙烯保温板,厚度为75mm,彩钢板厚度0.426mm, 顶板采用优质镀锌钢板折弯拼装而成。 | ||

| 2、房体四周边框:镀锌钢板装饰;钣金喷粉大门,方型观察窗 | |||

| 3、地台:采用1.5mm镀锌钢板、防锈蚀处理钢架结构拼装,地台高度300mm配置两道麻花格栅、三道花纹板和三件宽600mm上车坡。 | |||

| 送排风系统 | 二台4kw双进风离心式外转子送风机:风量外转子风机;风量:2000m3/h,风柜由喷涂型材、镀锌钢板制成;侧上进风,排风管由优质镀锌钢板、专业设备制成的法兰组成。有载风速:0.35 m/s ;换气次数:280time/h | ||

| 净化系统 | 顶部高效进口立体喷胶棉(VF-600)。 采用精粗两道过滤层结构:粗效采用优质无纺棉,能有效捕捉大于15μm的尘粒,在发生柜进风口处,设置活动门便于更换;精密级过滤层采用意大利技术生产的高效过滤棉,该过滤棉具有多层结构,能有效捕捉大于5μm的尘粒。设置在静压室底部,用防腐方管承托,美观、大方,容易更换。整个净化系统容尘量大、风阻小、寿命长,过滤率达98%。地棉过滤为意大利技术生产的玻璃纤维棉 ;TSP值≤1.4mg/m³。 | ||

| 加热系统 | 1、采用利雅路G20型轻油燃烧器,每小时产生热量为18万大卡,每台车耗油量为5~8公升/台,升温时间6~8分钟(20-60℃)。 | ||

| 2、热能转换器采用1.5mm厚优质不锈钢氩弧焊接而成,结构合理、安全可靠、热交换面积大,热利用效率高。 | |||

| 照明系统 | 在房体的顶侧部及两侧壁安装照明灯组,顶侧灯组呈45°角安装,由24支36瓦菲利浦灯管组成,垂直安装在墙板内,室内光照度达900Lux以上。 | ||

| 电控系统 | 采用优质电子元件组装,主回路设有多重保护。设有照明开关、温度时间设置、常温喷漆、恒温喷漆、烤漆开关、紧急停止开关、累计时等 | ||

| 废气处理 | 直排:可选配环保柜 | ||

| S-58 | |||

| Outer dimension:(mm) | Inner dimension:(mm) | Front door size | Total power |

| 7000*5300*3300 | 6900*3900*2800 | 3000(w)*2700(h) | 10kw |

| Appearance color | Red blue white orange | ||

| Frame system | Flame retardant polystyrene insulation board,50mm thickness,galvanized steel assembled roof. Aluminium alloy front door frame and galvanized steel fixed room frame.The floor is assembly formed by corrosion-resistant rectangular tube with 3 rows of grids and 2 rows of checkered plates. | ||

| Air circulation system | 2*4kw double channels centrifugal outer-rotor ventilating machines,air flow:24000m3/h, exhaust duct is formed from superior galvanized steel and flange;On load air speed:0.35m/s;Air exchange rate:280 times/h | ||

| Filter system | High-efficiency imported glue-spreading cotton(VF-600) ceiling filter.USES pure thick two filter layer structure: coarse efficiency high quality cotton, can effectively catch dust is greater than 15 microns, in the event of a tank into FengKouChu, sets the active door is convenient for replacement; Precision filter layer adopts Italian technology in the production of high efficiency filter cotton, the filter cotton has a multilayer structure, can effectively capture the dust particles is greater than 5 microns. Set in the static pressure at the bottom of the chamber, with anticorrosive pipe retainer, beautiful, generous, easy to replace. The large amount of dust cleaning system capacity, small wind resistance, long service life, the filtration rate was 98%. Cotton filter for Italy technology production of glass fiber cotton; The TSP values after 1.4 mg/m or less. | ||

| Heating system | Type 1, using riello G20 light oil burner, heat of 180000 kcal per hour, each vehicle fuel consumption for 5 ~ 8 litres/units, heating up 6 ~ 8 minutes (20 to 60 ℃). | ||

| 2, heat energy converter using 1.5 mm thick high quality stainless steel argon arc welding and become, rational structure, safe and reliable, large heat transfer area, high heat utilization efficiency; | |||

| Lighting system | Side and two side wall at the top of the building to install lighting chy-tech, top side chy-tech 45 ° Angle of installation, is composed of 24 36 watts Philip tube, vertical installed inside a wall, indoor light more than 900 lux. | ||

| E-controlling system | Adopt superior electronic components,main circuit has multi-protection. | ||

| Function:Lighting switch,heating time setting,normal temperature painting,constant temperature painting,drying switch,emergency stop switch,cumulative time etc. | |||

| Waste gas treatment | Direct vent. | ||

| Optional | Environmental protection device | ||

鲁公网安备 37061102001097号

鲁公网安备 37061102001097号